Livestock play an integral role in the livelihood of poor farmers by providing economic, social and food security. According to FAO, 2011 the world would need 73% more meat and 58% more milk in 2050. So, to meet these demands, huge quantity of feed resources will be required. Already there is a considerable shortage of feed availability in most developing countries.

Livestock play an integral role in the livelihood of poor farmers by providing economic, social and food security. According to FAO, 2011 the world would need 73% more meat and 58% more milk in 2050. So, to meet these demands, huge quantity of feed resources will be required. Already there is a considerable shortage of feed availability in most developing countries.

In India a shortage of 25, 159 and 117 million tonnes of concentrates, green forages and crop residues, constituting respectively a shortage of 32, 20 and 25 percent of the requirement has been estimated (Ravi Kiran et al., 2012). The area under fodder production cannot be increased due to increasing human population and urbanization. The global price of feed ingredients such as maize, wheat, fish meal and soybean meal has increased by 160, 118, 186 and 108 percent, respectively in the last decade, while the price rise in livestock products such as poultry meat, pork and lamb was only 59, 32 and -37 percent respectively, while that of beef was 142 percent (Index Mundi, 2013). Under these conditions, to meet the nutrient requirements of livestock and to sustain their productivity and profitability seem only possible if non-conventional, alternate feed resources are explored.

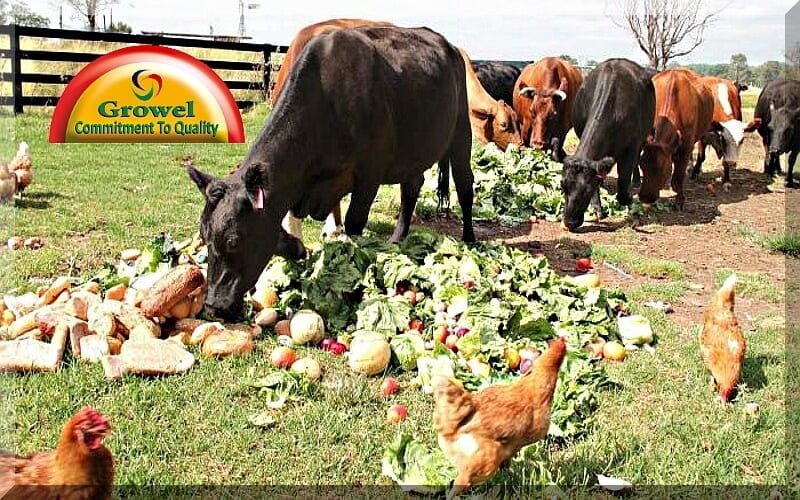

A strong shift in the cropping pattern from cereals to more remunerative fruit and vegetable crops in many countries will lead to decreased supply of cereals and crop residues to animal feeding. This change has resulted in generation of huge quantities of fruit and vegetable byproducts and wastes. For example, fruit and vegetable processing, packing, distribution and consumption in the organized sector of India generate approximately 1.81 million tonnes of fruit and vegetable wastes (Table 1). These are either composted or dumped in landfills or rivers, causing environmental hazards. Alternatives to such disposal methods could be recycling through livestock as feed resources and further processing to extract or develop value-added products. Such an approach will convert “wastes to opportunities for development” in addition to contributing to sustainable intensification of livestock industry. Such unconventional resources can act as an excellent source of nutrients and help to bridge the gap between demand and supply of feedstuffs for livestock.

Fruit Waste as Livestock Feed:

Apple (Malus domestica)

India ranks third in apple production and contributes 4.10 % to world. India produces 2.89 million tones of apple annually according to 2011-2012 census. Out of total production 30–40 percent of apples are damaged and therefore not marketed, and 20–40 percent are processed for juice extraction. So, the residue left after extraction of the juice, called apple pomace, could be used as a livestock feed.

Ruminants :

Nutrients in the dried apple pomace :

Crude Protein – 7.7 %

Ether Extract – 5 %

It has 1.86 Mcal metabolizable energy (ME)/kg DM and 1.06−1.12 Mcal net energy (NE)/kg DM for lactating dairy cows (NRC, 2001).

The ensiled apple pomace, incorporated up to 30 percent in the diet of lactating cows, did not show any adverse effects on milk yield or its composition. However, the best feed conversion ratio was observed at 15 percent incorporation in the diet (Ghoreishi, Pirmohammadi and Yansari, 2007).

Non-Ruminants :

The dried apple pomace can be used as an energy source in broiler rations replacing maize by 10 percent (w/w), without adversely affecting the broiler production. Incorporation at >10 percent leads to production of wet litter and depresses feed efficiency, mainly due to higher fibre content. The ME of apple pomace for broilers is 2.6−2.8 Mcal/kg DM. Matoo et al. (2001) have reported better performance of broilers fed on apple pomace diets supplemented with a commercial enzyme preparation (α-amylase, hemicellulase, protease and β-glucanase) compared with those that were not supplemented. The dried, ground damaged apple can replace 20 percent maize in broiler ration without any harmful effect and thus decreasing the feed cost.

Banana (Musa acuminata) :

India ranks First in banana production and produces 29.78 million tones of annual production. Out of total production 30-40 % is rejected for failing to meet quality standards and is potentially available for feeding to livestock (Babatunde, 1992). Banana wastes include damaged bananas, banana peels, leaves, young stalks and pseudo stems, which can be fed to livestock.

There are two main types of bananas used for livestock feed :

- when ripe consumed as a fruit (represent 56% of world banana production)

- plantains – used for cooking or making beer, vinegar, chips or starch (represent 44% of world banana production)

Fresh plantain and banana fruits may be ensiled with molasses, grass, legumes, rice bran etc. Green fruits are easier to ensile than ripe fruits.

Banana peels :

Banana peel constitutes about 30 percent of fresh banana by weight. These can be fed to livestock as fresh green, ripe or dried.

Composition :

Ripe banana peels contain up to 8 percent CP and 6.2 percent EE, 13.8 percent soluble sugars and 4.8 percent total phenolics (Table 4) (Bakshi and Wadhwa, 2013). Banana peels are rich in trace elements, but Fe, Cu and Zn contents are much higher than the maximum tolerance limit for ruminants (Table 7), suggesting that these should not be fed ad libitum, but should be supplemented in the ration of ruminants as source of organic minerals.

Green peels have approximately 15 percent starch which gets converted to sugars as the fruit ripens and the ripened peel has approximately 30 percent free sugars.

Green plantain peels contain 40 percent starch.

Lignin content also increases from 7 to 15 percent with ripening. Tannins mostly present in the peels are responsible for the astringent taste of immature fruits, which adversely affect their palatability in monogastric animals, while there is no palatability problem with peels of the mature/ripened fruit. Ripening causes migration of tannins to the pulp or they get degraded by polyphenol oxidases and peroxidases (Emaga et al., 2007).

Ruminants :

Banana peels are widely used by small, marginal and landless farmers as complementary feeds for ruminants in the tropics. Their nutritive value is similar to that of cassava or citrus peels.

- Dairy cows fed 14−21 kg of fresh ripe banana peels increased milk production (Dormond, Boschini and Rojas, 1998). In grass-fed Zebus, the addition of 15−30 percent banana peels in the diet increased weight gain significantly without causing health problems or affecting palatability (Hernan Botero, Enrique Toro and Rios, 2000).

- In goats, dry ripe plantain peels can replace up to 100 percent maize without adversely affecting growth performance, and were found to be an economical source of carbohydrates (Aregheore, 1998).

Non-Ruminants :

- Dried ripe banana peels can be fed to growing pigs up to 20 percent in the diet without depressing growth (Rios, Abernathy and Nicholas, 1975).

- Sun dried ripe plantain peels could replace 75−100 percent of maize in weaned rabbit diets.

- Dried banana peels incorporated up to 10 percent in broiler diets improved the live weight gain and feed conversion efficiency. However, inclusion beyond 10 percent in the diet depressed the growth.

Citrus :

India ranks fourth in world for citrus production with 7.8 million tonnes of production. The main citrus processing country in the world is Brazil which processes 47 percent of the world’s citrus fruits.About 30 percent of the production of citrus fruits is processed principally to make juice .

Citrus Pulp :

Citrus pulp is usually made from oranges (60 percent), grapefruits and lemons.The residue left after extraction of the juice is called citrus pulp (50−70 percent of the fruit by weight). It contains 60−65 percent peel, 30−35 percent internal tissues and up to 10 percent seeds (Crawshaw, 2004). Adult crossbred cattle can consume 50−60 kg fresh citrus pulp daily. But it is perishable due to the presence of high contents of water and soluble sugars and may cause environmental pollution. It should be sun dried and pelleted to increase density or should be ensiled. While drying, lime is added to neutralize the free acids, bind the fruit pectins and release water (Wing, 2003).

Composition : Citrus pulp contains (Crawshaw, 2004; Bakshi and Wadhwa, 2013)

CP- 5-10 %

EE- 6.2 %

Soluble fibre (pectins)- 10-40 %

Water soluble sugars- 54 %

Calcium- 1-2 %

Phosphorus- ).1 %

Citrus pulp is a rich source of trace elements and their concentration is much below the maximum tolerance limit for ruminants.

Ruminants :

- Dried citrus pulp is used as a cereal substitute in concentrate diets due to its high OM digestibility (85−90 percent) and energy availability (2.76−2.9 Mcal ME/kg DM and 1.66−1.76 Mcal NE/kg DM) for lactating dairy cows. Unlike cereals, its energy is not based on starch but on soluble carbohydrates and digestible fibre. Citrus pectins are easily and extensively degraded, producing acetic acid, which is less likely than lactic acid to cause a pH drop and result in acidosis (Wing, 2003).

- Due to its high fibre content, the long rumination of citrus pulp produces large quantities of saliva that has a buffering effect on rumen pH. Citrus pulp is therefore considered as a safer feed than cereals for animals fed high-concentrate, low-roughage diets as in high-yielding dairy cows (Crawshaw, 2004).

- Dried citrus pulp can replace 20 percent concentrate in dairy cattle (Assis et al., 2004) and up to 30 percent in lactating ewes (Fegeros et al., 1995) without adversely affecting DM intake, rumen metabolites, digestibility, milk yield or milk protein and fat contents.

- Animals should be adapted gradually because it contains limonin in the seeds and peels, which has a bitter taste. Utilization of fruit and vegetable wastes as livestock feed

- Large amounts of butyric acid produced as a result of the high-level feeding cause rumen papillae to become enlarged and keratisined, restricting nutrient absorption and impairing animal performances (Brugere-Picoux, 2004).

Non-Ruminants :

- It is much less valuable to pigs and poultry due to the fibre content and to the presence of limonin in the seeds, which is toxic to monogastrics (Gohl, 1982). The presence of limonin in the seeds of citrus pulp may be a limiting factor. Dried citrus pulp may be included up to 5 percent in the diet of growing pigs. Higher rates (>10 percent) can adversely affect growth rates, feed conversion efficiency and carcass yield.

- The level of citrus pulp in the diets of poultry should not exceed 5−10 percent because of the presence of non-starch polysaccharides which impaired growth rates, lowered feed efficiency and reduced carcass yields (Mourao et al., 2008). But within these limits (up to 10 percent) it did not affect feed intake, egg production, and egg weight in laying hens (Yang and Chung, 1985).

Citrus Molasses :

It is a by-product of citrus juice extraction. The fresh pulp mixed with lime is pressed to remove moisture. The resulting liquid (press juice) is screened to remove the larger particles, sterilized and concentrated. It is a thick, viscous dark brown to almost black liquid, and is called citrus molasses. It has bitter taste due to the presence of naringin, a flavonoid (Hendrickson and Kesterson, 1965). Its composition (60−65 percent sugars and 4−5 percent CP) is comparable to sugarcane molasses. It can be fed to animals, or added to grass silage.

Ruminants :

In spite of the bitter taste, it is readily accepted by beef and dairy cattle and is as palatable as sugarcane molasses. It may be mixed with pressed pulp prior to drying, which increases the total digestible nutrient (TDN) content in the dried product without affecting the keeping quality of the pulp. Cattle can consume up to 3 kg/day when offered ad libitum (Gohl, 1978).

Non-Ruminants :

Citrus molasses is not palatable to pigs, but pigs can be adapted in 3−7 days and it can subsequently replace 10−40 percent of maize depending on the age of the pig (Hendrickson and Kesterson, 1965).

Table No. 1 Production of fruits (million tonnes) in India and world in 2010−11

Table No. 2 Nutritional composition of Fruits

Table No. 3 Macro mineral content (percent DM basis) of fruit wastes

Table No. 4 Micro mineral content (ppm) of fruit wastes

Vegetable Waste as Livestock Feed :

Tomato (Lycopersicon esculentum) :

Tomato waste is made up of,

- Culled Tomatoes – The culled fruits may be damaged, diseased, too small, misshapen etc. and do not meet the grading standards for sale in the fresh market or for processing.

- Tomato Pomace – Tomato pomace is a mixture of tomato peels, seeds and small amounts of pulp that remains after processing of tomato and is fed after sun drying and grinding.

Unripe tomatoes and the green parts of ripe tomatoes contain a solanine-like alkaloid (saponin) called tomatine that may be toxic to insects, dogs and, to a lesser extent, herbivores (diarrhea, vomiting, intestinal irritation). However, it disappears as the tomato ripens and is not a problem in tomato pomace.

Cull Tomatoes :

Fresh culled tomatoes contains,

- CP -14−20 percent

- EE – 4−5 percent

- ADF – 22 percent.

Tomatoes contain 40−60 percent non-structural carbohydrates; 90−95 percent of them are soluble sugars and 5−10 percent pectins (ANSES, 2008; Ventura, Pieltin and Castanon, 2009).

Ruminants:

Cull tomatoes are slightly more digestible than tomato pomace as they contain all the highly digestible pulp and less fibre. The in vitro OM digestibility of fresh tomatoes was 63 percent, providing a DE value of 2.59 Mcal DE/kg DM. Fresh cull tomatoes can be fed up to 1.5 kg to male goats with ad lib ryegrass hay without digestive disorders (Ventura, Pieltin and Castanon, 2009).

Non-Ruminants:

Dried cull tomatoes satisfactorily replaced alfalfa meal at 3 percent of the diet for broilers.

Tomato pomace

Ruminants:

Tomato pomace (TP) can be fed fresh or can be preserved either by sun drying or by ensiling. Because of the high moisture content, it cannot be ensiled alone. Therefore, it is recommended to mix with wheat or rice straws or maize stovers in 70:30. TP contains

- 19−22 percent CP and

- 11−13 percent EE,

- while acid detergent lignin (ADL) content varies between 7−13 percent (NRC, 1989; Bakshi, Kaur and Wadhwa, 2012).

It is a good source of lycopene, a pigment that gives colour to meat, and is a known antioxidant. It has 2.37 Mcal ME/kg DM and 1.43−1.53 Mcal NE/ kg DM for lactating dairy cattle (NRC, 1989). In multiparous dairy cows (26 kg milk/day) dried tomato pomace could be included up to 32.5 percent in the concentrate mixture without any adverse effect on health, milk yield and DM intake (Belibasakis, 1990). The sun dried, ground TP could replace the concentrate mixture completely in the diet of male buffaloes without affecting DM intake, digestibility of nutrients, urinary purine derivatives, microbial protein synthesis and total volatile fatty acids (VFAs) production in the rumen (Bakshi, Kaur and Wadhwa, 2012). Dairy cows fed TP (fresh) maize silage had DM intake (3.74 percent BW), milk yield (35 kg/day) and milk composition comparable with the cows fed with maize silage alone (Weiss, Frobose and Koch, 1997). Caluya et al. (2003) recommended that tomato pomace (fresh, dry or ensiled) can replace 50 percent of the roughage.

Non -Ruminants :

- Fresh TP can be used at 6 percent and 35 percent as a supplement feed in grower and finisher pigs respectively without any adverse effect on their performance and by decreasing feed cost/kg gain.

- Dried TP can be introduced up to 20 percent in the diet of growing rabbits without significantly affecting performance (Sayed and Abdel-Azeem, 2009).

- Dried tomato pomace can be included up to 10−20 percent without any adverse effect on egg production, body weight (Calislar and Uygur, 2010) and overall egg quality (Salajegheh et al., 2012), while higher levels may depress hen-day production (Jafari, Pirmohammadi and Bampidis, 2006).

Potato (Solanum tuberosum L.)

During the peak production season, it becomes a problem for the farmers to dispose of the surplus and the cull potatoes. These cannot be dumped, even in the waste land, because of the legal implications. Also, such potatoes cannot be kept in the cold stores because of the cost involved. The only option for the farmers is to feed them to the livestock. Raw potatoes are not very palatable and have a laxative effect and, therefore, should be introduced gradually in the diet of animals. To get the most value from the starch present in potatoes, these should be boiled or steamed. Potato sprouts contain an alkaloid, solanine, and it is advisable to remove the sprouts before the potatoes are fed to pigs or poultry. Fungal infested potatoes should never be used as feed.

Composition :

The fresh potatoes contain 65−75 percent starch (depending on the variety), 9.5 percent CP and 0.4 percent EE on dry matter basis. Potatoes contain negligible quantities of fibrous fractions like NDF, ADF and cellulose.

Ruminants :

Potatoes have high ME (3.16 Mcal/kg DM) and NE (1.87 Mcal/kg DM) for lactating dairy cows (NRC, 1989). Dairy and beef cows can be fed up to 15−20 kg/day of raw potatoes without any adverse effects on the health of the animals (De Boever et al., 1983). Potato tubers can be chopped with forage and ensiled. The heat generated during the fermentation is sufficient to cook the potatoes. The haulm can be ensiled for feeding to cattle.

Non-Ruminants :

Pigs are usually given only cooked potatoes, which are efficiently used by fattening and breeding animals. Pigs can be fed up to 6 kg a day. Potatoes produce firm pork.

Cooked potatoes can be used for poultry up to 40 percent of the total ration (Edwards, Fairbairn and Capper, 1986).

Carrot (Daucus Carota)

Feed carrots are usually cull (grade-out) or surplus carrots obtained during glut season of production. These can be fed fresh (whole/chopped), ensiled or dehydrated. Other carrot products that occasionally are fed to livestock include the carrot tops and carrot pomace after extraction of juice.

Composition:

Fresh carrot contains,

- 10 percent CP,

- 1.4 percent EE

- up to 60 percent sugars, mostly sucrose (on DM basis).

- A rich source of vitamin C (300−700 mg/ kg DM) and carotene, depending on the carrot variety; orange carrots contain 200−1000 mg/kg DM of β-carotene (ANSES, 2008). Carrots also contain harsh turpentine-like flavors associated with the presence of total volatiles especially γ-terpenine and elicit a negative organoleptic response and decrease in palatability when in high concentration (Simon, Peterson and Lindsay, 1980).

Ruminants :

- Carrots are highly palatable and readily consumed by cattle. Carrots are a rich source of ME (3.29 Mcal/kg DM) and NE (1.94 Mcal/kg DM) for lactating dairy cows (NRC, 1989).

- Fresh carrots can be fed up to 20 and 25 kg/day to young bulls and dairy cows (Morel d’Arleux, 1990) and can be included up to 40 percent in the diet of steers, without any adverse effects (Rust and Buskirk, 2008). Due to high fermentable sugars, fresh carrots should be combined with fibrous feeds to prevent acidosis and scouring, and should be introduced progressively in the diet (8−10 days).

- The mixture of carrots and concentrate feed should not exceed 50 percent of the diet DM and ad libitum feeding must be prevented (Morel d’Arleux, 1990).

Prolonged use of carrots in the diet of dairy cows increased the carotene content of the milk and producedyellow coloured milk fat (Fuller, 2004). A significant improvement in the reproductive

performance of high-yielding cows fed 10 kg/day fresh carrots in the diet was observed; a decrease in the calving interval from 167−185 days to 110−171 days, a decrease in the number of inseminations necessary for successful fertilization (1.8−2.7 to 1.0−1.8) and an increase in the calving rate (84.5 to 92 percent). The milk yield and fat content were not affected (Car, 1985).

- The gestating and lactating ewes fed 3.3 kg/day fresh carrots during the last month of gestation and 5 kg/day (27 percent of the dry matter intake, DMI) during lactation were well accepted by the animal. It could be included up to 80 percent in the diet of ewes at maintenance.

- Goats can be fed up to 2−4 kg/ day of fresh carrots (Morel d’Arleux, 1990).

Non-Ruminants :

- Carrot is a staple diet of horses. Dehydrated carrots and carrot flakes are common commercial treats for horses. Fresh carrots are used in low amounts (2−3 kg/day) for working horses, and these are mostly used to maintain appetite and facilitate the consumption of dry feeds. Clean and well-preserved carrots can be fed up to 10 kg/day to resting or convalescent horses (Wolter, 1999). They should be chopped into 5 mm thick rings (Kohnke, Lelleher and Trever-Jones, 1999) or sliced into long thin slivers (Vogel, 2011) before feeding to reduce the risk of choking.

- Silage containing 17 percent carrots (with fodder beets, sugar beets and potatoes) fed to replacement sows had a positive effect on live weight gain, reproductive parameters and on litter performance. Similar results were obtained on lactating and gestating sows fed silage containing 12 percent carrots with pumpkins and potatoes (Yushkova and Kertieva, 2010).

- Carrots can provide carotenoids to laying hens. The yolk colour of the egg was improved

significantly when 4−8 percent dried carrot meal was used in the diet of laying hens compared with a wheat-based control diet.

Carrot Tops

Ruminants :

Carrot tops contain,

- 11−12 percent CP,

- 17 percent crude fibre and

- up to18 percent ash due to residual dirt.

Non-Ruminants :

- Carrot tops can be included up to 20−30 percent in diets of growing rabbits replacing Trifolium alexandrium hay with improved growth performance and feed conversion efficiency (Eleraky, 1996).

- Carrot tops fed at 5 percent to laying hens improved s-carotene content of egg yolk and did not affect egg weight, Haugh unit, egg-shape index and strength and thickness of the eggshell (Ishikawa et al., 1999).

Carrot Pomace :

Ruminants :

After extraction of juice, approximately one-third of the raw material remains as pomace. It contains 7−8 percent CP and 1.8 percent EE. It is a rich source of total sugars (64.3 percent) and contains about 4.3 percent total phenolics. The fractionation of true protein revealed that like other cannery wastes, it is rich in albumin, followed by glutelin, globulin and prolamin . It is also a rich source of macro- and micro-elements.

Non-Ruminants :

Dried carrot pomace could be used up to 50 percent in growing rabbit’s diets without any adverse effects on the productive performance, nutrient digestibility and blood components (El-Medany, Hashem and Abdel-Azeem, 2008).

Table No. 5 Production of vegetables (million/ tonnes) in India and world 2010-11

Table No. 6 Nutritional composition of Vegetables

Table No. 7 Macro mineral content (percent DM basis) of vegetable wastes

Table No. 8 Micro mineral content (ppm) of vegetable wastes

Conservation of Fruits & Vegetable Waste :

The majority of fruit and vegetable wastes like tomato pomace, bottle gourd pomace, citrus pulp, carrot pulp, baby corn husk and forage, cabbage and cauliflower leaves, sarson saag waste and pea pods, pineapple waste and pineapple bran etc. are highly fermentable and perishable, mainly because of high moisture (80−90 percent), total soluble sugars (6−64 percent) and crude protein (10−24 percent) contents. During the peak production or processing season, huge quantities of these resources are available and cannot be consumed at the same pace as they become available and thus become surplus and can cause environmental pollution. Therefore, suitable methods should be adopted to conserve such resources so that these can be fed to the livestock throughout the year or specifically during the lean period of green fodder production. This will also help mitigate environment pollution. The most commonly used methods are,

- Drying

- Ensiling

Drying :

- Fruit and vegetable wastes such as fresh apple pomace, tomato pomace, bottle gourd pomace (muddy in texture), pineapple bran and carrot pulp contain about 90 percent water.

- Keep the fresh waste in a heap on a slant till the excess water is drained out.

- Press mechanically by using filter press.

- Dry the waste by thermal drying: by blowing hot air or by using a solar drier.

- In case a mechanical press or thermal drying facilities are not available, then the waste may be spread in a 5–7 cm thick layer on a concrete floor under direct sunlight for sun drying. Wastes such as chaffed banana foliage, pea pods, tomato pomace and snow peas can be easily sun dried.

- Turn the material upside down with a fork, 2−3 times a day, till the dry matter reaches around 90 percent. In peak summer (40−45 οC), the desired dry matter is achieved within 2−3 days.

- Ground the dried waste in a Willey mill using 1−2 mm screen.

- Store the ground waste in polythene bags and use as and when required.

Ensiling :

Ensiling can be done by two methods as,

- Bunker or pit silo

- Tube silo

Conservation of fruit and vegetable wastes by ensiling in bunker or pit silo :

- The green leafy wastes can be conserved in bunker- trench or pit silo, depending on the quantity of the material to be ensiled.

- Environment temperature should be between 10 and 38 oC, the optimum being 32 oC.

- The size of the pit should be length 10 m × width 3 m × depth 1.5 m. One cubic meter can accommodate approximately 0.5 tonnes green waste; and accordingly keeping in view the availability of waste, the size can be adjusted.

- Wilt the wastes like banana foliage, cabbage and cauliflower leaves with stem, baby corn husk or baby corn forage for 1−2 days in the open, then chaff to 3−5 cm.

- Mix the wilted, chaffed wastes with either chaffed wheat straw, rice straw or maize stovers in a 70:30 ratio.

- Spread on the floor of the trench or pit a 5−7 centimeter layer of any poor quality crop residue to absorb the effluents released during fermentation.

- Fill the pit with uniformly mixed waste and straw/stover layer after layer in batches of 40 to 60 kg by trampling.

- Ensure that no air is trapped in the chaffed waste, till the pit is filled. In case of large silos, the pit is filled directly with the help of chaff cutter cum blower followed by pressing or packing with a tractor.

- Seal the silo pit/trench properly with polyethylene sheet and a layer of mud. Allow it to ferment for 42 days. As the mud sealing dries up cracks may appear which need to be sealed.

- Open the trench/pit after 42 days; remove silage as per the daily requirement and cover the pit again with a polyethylene sheet.

Conservation of fruit and vegetable wastes by ensiling in tube silo :

- The green leafy material can also be conserved in a 10 to 12 feet long, 60−80 μ thick, low density polyethylene (LDPE) tube of 6 feet diameter. It can accommodate 0.5 tonnes of green waste.

- Environment temperature should be between 10 and 38 oC, the optimum being 32 oC.

- Tie one end of the tube tightly with nylon string.

- Wilt the wastes (banana foliage, cabbage and cauliflower leaves with stem, baby corn husk or baby corn forage) for 1−2 days in the open, then chaff to 3−5 cm.

- Mix the wilted, chaffed wastes with either chaffed wheat straw, rice straw or maize stovers in a 70:30 ratio and ensile for 42 days.

- Before ensiling, spread a 5−7 centimeter layer of any poor quality crop residue at the bottom of the LDPE tube (to absorb the effluents released during fermentation).

- About 40−60 kg is transferred each time; then after manual pressing transfer another batch and again press (so as to ensure that no air is trapped in the waste material) till the LDPE tube is filled.

- After packing, seal the tube tightly at the top end with a nylon string.

- After 42 days, take out the silage from the tube as per the daily requirement and again seal the tube at the top end with a string.

- Ensiling in an LDPE tube is preferred over trench silo by landless, marginal and small dairy farmers because it reduces the initial infrastructure investment and it is easy to handle.

Conclusion of Fruit and Vegetable Wastes as Livestock Feed:

Fruit and vegetable wastes like apple pomace, tomato pomace; citrus, carrot and bottle gourd pulp; banana and mango peels etc. are a rich source of nutrients and these can be fed either as such, after drying or ensiling with cereal straws, without effecting the palatability, nutrient utilization, health or performance of livestock. The effective and efficient utilization of fruit and vegetable wastes will reduce the cost of animal feeding thereby increasing farmers’ profits, generate an array of value-added products and help in waste management and reduction of environmental pollution. It is concluded that most of the tested fruit wastes, especially banana foliage and peels, mango peels and seed kernels, citrus pulp and pineapple waste either fresh, dried or ensiled could serve as excellent alternative feed resources for livestock and poultry. It is concluded that baby corn husk, cabbage leaves, cauliflower leaves, sarson saag waste, tomato pomace, carrot pomace, cull potatoes, cull snow peas and pea pods could serve as excellent sources of nutrients for ruminants and can reduce the cost of feed production.You should also read How to Cut Cattle Feeding Costs

If you are into dairy or cattle related business & want to earn maximum profit in your business then please join our Facebook group How To Do Profitable Poultry & Cattle farming ?

An Ultimate Immunity Builder for Cattle & Poultry Composition : Each 10 ml contains: Vitamin – E : 35 mg Selenium : 10 ppm Glycine : 100 mg Amla : 30 mg Sodium Citrate : 25 mg Potassium Chloride : 5 mg Manganese Sulphate : 7.5 mg Zinc Sulphate : 8.0 mg Yeast Extract : 35 mg Vitamin B 12 : 3 mcg In a base fortified with immunoactive polysaccharides Indications & Benefits :

Dosages: For 100 Birds : Broilers : 10 – 15 ml Layers : 15 -20 ml Breeders : 25-30 ml For Cattle : Cow & Buffalo : 40-50 ml Goat,Sheep & Pig : 25-30 ml Should be given daily for 7-10 days or as recommended by veterinarian. Packaging : 500 ml 1 ltr. & 5 ltr. | A Powerful Chelated Minerals Supplements for Cattle & Poultry Composition : Each 500 ml contains: MHA : 128 gm Choline Chloride : 64 gm Lysine Hydro Chloride : 64 gm Sodium : 450 mg Phosphorus : 154 mg Magnesium : 595 mg Zinc : 216 mg Ferrous (Iron) : 223 mg Copper : 160 mg Cobalt : 206 mg Manganese : 385 mg Indications & Benefits : Poultry:

For Cattle:

Dosages: For 100 Birds: Broilers : 5-10 ml. Layers & Breeders : 10-20 ml. For Cattle : Cow & Buffalo : 30-40 ml. Goat, Sheep & Pig : 10-20 ml. Should be given daily for 7-10 days ,every month or as recommended by veterinarian. Packaging : 500 ml. , 1 ltr. , 5 ltr. |